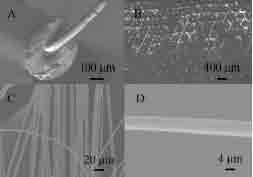

| Zhang et al. report a novel fiber drawing method for forming very long metallic wires with micron to nanometer sized diameters. This method is amenable to scale up for producing vertically aligned arrays of these micro/nanowires in large quantities. |

Reviewed by Dr. Douglas E. Betts, University of North Carolina at Chapel Hill

The production of ordered arrays of nanometer to micron diameter wires is a challenge by today’s conventional processes using chemical or physical vapor deposition, porous matrices of silica, alumina, or anodized aluminum oxide, or lithographic processes such as photolithography, focused ion beam or electron beam or soft imprint lithography. These techniques suffer from being slow, expensive, and difficult to translate to mass production. Furthermore, they typically result in tangled, horizontally arranged, or surface bonded structures in limited lengths and low yields. Xuejun Zhang and colleagues present in Advanced Materials an ideal method for making wire arrays with nanometer to micron-size diameters in high yields over large areas that can potentially be scaled up to produce vertically aligned micro- or nanowires at meter lengths in large volumes.

In practice, it is very important to closely match the melting point of the metal alloy to the drawing temperature of the glass as changes in composition resulting from the evaporation or migration of components in the alloy result in thermophysical and mechanical property changes in the wires that affect the drawing resistance of the glass and the final diameter obtained. Zhang et al. cite examples of micro/nanowires made from copper/phosphor, zinc, and tin with some problems reported but by using glass with the appropriate chemical, thermophysical, and surface properties it should be possible to make large quantities of vertically aligned micro/nanowires of almost any metallic material.

Image from Xuejun Zhang, Zeyu Ma, Zhong-Yong Yuam, and Ming Su (2008). “Mass-Productions of Vertically Aligned Extremely Long Metallic Micro/Nanowires Using Fiber Drawing Nanomanufacturing,” Advanced Materials 2008 (20) 1310-1314. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported.