Researchers at the USC Viterbi School of Engineering have improved the performance and capacity of lithium batteries by developing better-performing, cheaper materials for use in anodes and cathodes (negative and positive electrodes, respectively).

Lithium-ion batteries are a popular type of rechargeable battery commonly found in portable electronics and electric or hybrid cars. Traditionally, lithium-ion batteries contain a graphite anode, but silicon has recently emerged as a promising anode substitute because it is the second most abundant element on earth and has a theoretical capacity of 3600 milliamp hours per gram (mAh/g), almost 10 times the capacity of graphite. The capacity of a lithium-ion battery is determined by how many lithium ions can be stored in the cathode and anode. Using silicon in the anode increases the battery’s capacity dramatically because one silicon atom can bond up to 3.75 lithium ions, whereas with a graphite anode six carbon atoms are needed for every lithium atom.

The USC Viterbi team developed a cost-effective (and therefore commercially viable) silicon anode with a stable capacity above 1100 mAh/g for extended 600 cycles, making their anode nearly three times more powerful and longer lasting than a typical commercial anode.

Up until recently, the successful implementation of silicon anodes in lithium-ion batteries faced one big hurdle: the severe pulverization of the electrode due to the volume expansion and retraction that occurs with the use of silicon. Last year, the same team led by USC Viterbi electrical engineering professor Chongwu Zhou developed a successful anode design using porous silicon nanowires that allowed the material to expand and contract without breaking, effectively solving the pulverization problem.

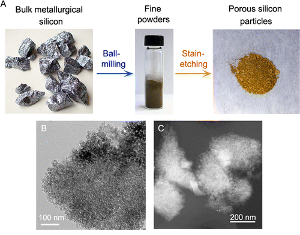

This solution yielded a new problem, however: the method of producing nanostructured silicon was prohibitively expensive for commercial adoption. Undeterred, graduate student Mingyuan Ge and other members of Zhou’s team built on their previous work to develop a cost-efficient method of producing porous silicon particles through the simple and inexpensive methods of ball-milling and stain-etching.

“Our method of producing nanoporous silicon anodes is low-cost and scalable for mass production in industrial manufacturing, which makes silicon a promising anode material for the next generation of lithium-ion batteries,” said Zhou. “We believe it is the most promising approach to applying silicon anodes in lithium-ion batteries to improve capacity and performance.”

In addition, graduate student Jiepeng Rong and other team members developed a method of coating sulfur powder with graphene oxide to improve performance in lithium-sulfur batteries. Sulfur has been a promising cathode candidate for many years owing to its high theoretical capacity, which is over 10 times greater than that of traditional metal oxide or phosphate cathodes. Elemental sulfur is also abundant, cheap, and has low toxicity. However, the practical application of sulfur has been greatly hindered by challenges including poor conductivity and poor cyclability, meaning the battery loses power after each charge and dies after a lower number of recharges.

Their research proved that a graphene oxide coating over sulfur can solve both problems. Graphene oxide has unique properties such as high surface area, chemical stability, mechanical strength and flexibility, and is therefore commonly used to coat core materials in products like sensors or solar cells to improve their performance. The team’s graphene oxide coating improved the sulfur cathode’s capacity to 800 mAh/g for 1000 cycles of charge/discharge, which is over 5 times the capacity of commercial cathodes.

Zhou and his team recently published their results on silicon anodes in Nano Letters [1]. The paper was a collaborative effort among Zhou, USC Viterbi graduate students Mingyuan Ge, Jiepeng Rong, and Xin Fang, as well as Matthew Mecklenburg from the Center for Electron Microscopy and Microanalysis at USC, and researchers from China’s Zhejiang University and Lawrence Berkeley National Laboratory. Separately, Zhou, Rong, Ge, and Fang also published results in Nano Letters on their method to easily produce graphene-coated sulfur cathodes for lithium-ion batteries [2].

Now that their separate tests of the negative and positive electrodes have yielded excellent results, the team is now working to test them together in a complete battery. They will next integrate the silicon anode with the sulfur cathode, as well as with other traditional cathode materials, in order to maximize lithium-ion battery capacity and overall performance.

“As far as we can tell, our technologies with both the silicon anode and sulfur cathode are among the most cost-effective solutions and therefore show promise for commercialization to make the next-generation of lithium-ion batteries to power portable electronics and electric vehicles,” said USC Viterbi graduate student Rong.

This research was supported by USC Viterbi, the Center for Electron Microscopy and Microanalysis at USC, the National Center for Electron Microscopy at Lawrence Berkeley Laboratory (supported by the U.S. Department of Energy under Contract DE-AC02-05CH11231), and the National Natural Science Foundation of China (11004171).

[1] M.Y. Ge, Y.H Lu, P. Ercius, J.P. Rong, X Fang, C.W. Zhou, M. Mecklenburg, “Large-Scale Fabrication, 3D Tomography, and Lithium-Ion Battery Application of Porous Silicon,” Nano Letters, 2014, 14, 261. DOI: 10.1021/nl403923s

[2] J.P. Rong, M.Y. Ge, X. Fang, C.W. Zhou, “Solution Ionic Strength Engineering As a Generic Strategy to Coat Graphene Oxide (GO) on Various Functional Particles and Its Application in High-Performance Lithium–Sulfur (Li–S) Batteries,” Nano Letters, 2014, 14, 473. DOI: 10.1021/nl403404v

About the USC Viterbi School of Engineering

Engineering Studies began at the University of Southern California in 1905. Nearly a century later, the Viterbi School of Engineering received a naming gift in 2004 from alumnus Andrew J. Viterbi, inventor of the Viterbi algorithm now key to cell phone technology and numerous data applications. Consistently ranked among the top graduate programs in the world, the school enrolls more than 5,000 undergraduate and graduate students, taught by 174 tenured and tenure-track faculty, with 60 endowed chairs and professorships. http://viterbi.usc.edu

Contact

Megan Hazle – 213-821-1887 or hazle@usc.edu

Image reprinted with permission from M.Y. Ge, Y.H Lu, P. Ercius, J.P. Rong, X Fang, C.W. Zhou, M. Mecklenburg, “Large-Scale Fabrication, 3D Tomography, and Lithium-Ion Battery Application of Porous Silicon,” Nano Letters, 2014, 14, 261. DOI: 10.1021/nl403923s. Copyright 2014 American Chemical Society.