Envia is a high energy density leader in the lithium-ion battery space. Having developed intellectual property and cell prototypes using proprietary cathode, anode and electrolyte, Envia is engaged with automotive OEMs around the world – developing custom electrode materials, electrolyte, and cell designs for these OEMs automotive applications. As a proof of technical leadership, Envia has also demonstrated the world’s first 1530 mAh/g lithium-ion battery in large format pouch cells. The key to achieving the world record energy density is combining Envia’s proprietary high capacity HCMR™ cathode with its proprietary high capacity Si-C anode. source

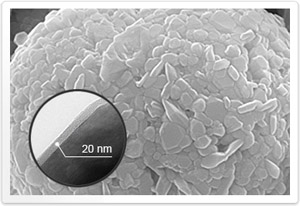

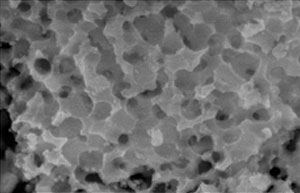

Envia’s unique cathode chemistry is based on a unique crystal structure developed by Argonne National Laboratory, which incorporates a layered materials structure composed of lithium manganate (Li2MnO3) and lithium metal-oxide (LiMO2). The Li2MnO3 is electrochemically inactive, whereas the LiMO2 is active with respect to lithium insertion/extraction. Embedding the inactive Li2MnO3 component within layered LiMO2 structure stabilizes the electrode and reduces oxygen activity at the surface of charged particles. As a result of this cathode materials strategy, Envia’s High Capacity Manganese Rich (HCMR™) cathode has excellent stability at high voltages and can access high capacities with long cycle life. Utilizing a proprietary nanocoating process further enhances the cathodes cycle life to >1000. Envia has built on Argonne’s layered materials chemistry to fine tune the composition of Ni, Co, Mn and Li2MnO3, with additional innovations on particle morphology (particle size, shape, distribution, tap density, and porosity). Furthermore, the development of novel nanocoatings provides enhanced cycle life and safety.

Envia has additionally developed an electrolyte that is stable up to a voltage of 5.2V (vs Li/Li+). In cyclic voltammetry studies of standard electrolytes, as the voltage window was opened from upper cut-off of 4.3V vs Li/Li+ the electrolytes showed an increase in oxidation currents. When the voltage window was further increased to voltages above 4.5V the oxidation currents increased significantly showing that the electrolytes were almost completely oxidized at these voltages. However, Envia’s high voltage electrolyte has shown stability up to 5.2V without any rapid increase in the oxidation currents. source

The testing of Envia’s next‐generation lithium‐ion battery was independently verified by the Electrochemical Power Systems Department at the Naval Surface Warfare Center (NSWC) in Crane, Ind., under the sponsorship of ARPA‐E. Tests at various cycling rates at NSWC confirmed that Envia’s automotive battery cell demonstrated energy density between 378‐418 Wh/kg for rates between C/3 to C/10 for a 45 Amp‐hour (C/3) cell. Similar cells have been cycling in Envia’s test labs for over 300 cycles. NSWC Crane will also test these cells to validate cycling performance. source