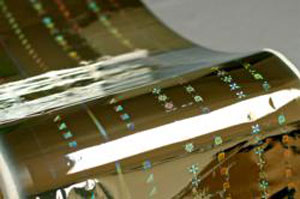

The third party which conducted the test-run is the same billion dollar company which conducted the first commercial scale run several months ago using clear polymer. The optical roll was produced using conventional roll-to-roll printing technology while being metallized using rapid evaporation of aluminum to produce a highly reflective thin film surface. Metallization of the roll creates a vibrant, crisp, ultra high definition image and security feature. Nanotech designed and manufactured the original set of master shims provided to the third party for the commercial scale trial. NOtES® is Nanotech’s sophisticated authentication feature which replicates nanoscale structures similar to those found on the wings of the iridescent blue Morpho Butterfly.

Commercial Level Scalability Demonstrated

Doug Blakeway, CEO and Chairman of Nanotech, states “We are pleased by the results of this test which demonstrated the robust nature and scalability of this technology. This test run involved creation, in a matter of minutes, of over 250,000 individual, iridescent optical images or plasmograms® which are visible to the naked eye meters away. This is a major breakthrough for the Company’s technical team, demonstrating that NOtES® can be seamlessly incorporated into commonly used, printing-press type manufacturing methods, including metallization.”

Mr. Blakeway added, “The results we’ve obtained so far are very positive and we have yet to run into any significant commercialization problems. We believe that we can produce our technology side by side with currently accepted authentication features to replace, complement and augment them.”

Nanotech Security Corp. has signed confidentiality agreements with a number of international parties who are closely following these technical test results.

The National Nanomanufacturing Network asked Nanotech Security Corp.’s Chief Technical Officer, Clint Landrock, to further discuss this announcement for our audience.

NNN: Is this technology meant to be incorporated directly into roll-to-roll and print manufacturing processes and resulting products, or will it be an add-on like a tag of some sort?

Clint Landrock: Our patented technology can be incorporated either by directly imprinting the material of the product which is to be authenticated, or imprinted onto a film and added later to a product similarly to how current holograms are applied. Certainly the option for direct imprinting is a new and exciting possibly for the industry.

NNN: What value-added products will be impacted by this technology?

Clint Landrock: Any products which require authentication will benefit from this technology. Security documents such as passports, bank cards, and of course currency; Important and often counterfeited electronic components such as batteries, capacitors, memory; automotive and aerospace components; designer items including clothing and jewelry; alcohol and tobacco taxation stamps. All of these products face counterfeiting as major issues in day to day business, our technology will help to authenticate the real from the fake beyond any doubt. In addition this is a true green technology that can be used as further branding component.

NNN: What other applications may be impacted by this technology outside of the security sector?

Clint Landrock: Manufacturing at the nanoscale means producing trillions of structures under extremely fast processing, and often the overall yields are too low to provide reliable or economical use of a technology. Recent examples of issues with poor yields are Qualcom's mirasol displays and Sharp's supply for the iPhone 5. Our first large industrial scale demonstrations of high speed roll-to-roll manufacturing of our nanoscale optics have shown very high yields. This means that costs will remain low, there will be no issues with meeting demand, and our customers will be satisfied knowing they are receiving a product which is near perfection. We cannot release the exact numbers yet on the yields, but we can say they far exceeded our own estimations as well as the third-party estimations which performed the manufacturing. Our nanoscale optics are incredible overt security devices, but we also envision similar structures being applied onto solar cells, windows, and screens (TVs, mobile devices etc.), among many other areas. Our group has already shown their potential use on solar cells and OLEDs, for which we currently hold additional patents on.

About Nanotech Security Corp

Nanotech Security Corp. is developing its nanotechnology for the authentication and anti-counterfeiting market under license from Simon Fraser University where it originated.

Founded in 1984, Nanotech Security Corp. has developed technology and services in areas of criminal justice, infrared night-viewing, tracking security and forensics.

Once development is complete, Nanotech products are expected to be usable both overtly through an image visible to the naked eye and also in a covert manner, including invisible (to the eye) authentication features which employ machine readable data. The images produce vibrant colours and seemingly moving images which allow observers to quickly identify the authenticity of a product to which an optical marker or tag is affixed. The technology works by using nano-scale structures - smaller than the wavelength of light - to capture ambient light using ultra high optical efficiency and high pixel density. These plasmograms® can be directly imprinted into nearly any surface including polymers, metals and even paper, becoming a part of the product itself. Its outstanding optical performance means it can be used without mirror-like coatings found on traditional security features like holograms, and can be applied as a transparent security window display. The company is working to enhance security firstly for bank notes but the practical applications are expected to be wide-spread – potential uses include authenticating legal documents, retail merchandise, concert tickets, tobacco tax-paid stamps, medical & credit transactional cards, visas & passports, pharmaceuticals and for brand recognition. More information on the company can be found at the Company’s website http://www.nanosecurity.ca or http://www.sedar.com

Source: Nanotech Security