| Incorporating the advantages of high conversion efficiency, scalable manufacturing, and facile integration strategies, PVDF nanofiber power generators provide the basis for self-powered textiles, embedded power sources for nanodevices and wireless sensors, and large area fabrics for portable electronics implementations. |

Reviewed by Jeff Morse, Ph.D, National Nanomanufacturing Network

Harvesting of power from mechanical energy sources existing throughout the environment provides an opportunity to generate renewable power on multiple scales. While macroscale examples of environmental power production include wind, water, and tidal resources, small-scale mechanical vibrations throughout the environment offer distributed energy that may be harnessed for portable electronics and autonomous sensor networks, or integrated with energy storage devices enabling uninterruptable auxiliary power.

Harvesting of vibrational energy sources has previously focused on utilizing inorganic materials systems with specific piezoelectric and semiconducting properties as nanogenerators. Materials sets and specific structures, such as PZT or ZnO nanowires, have demonstrated efficient performance, but suffer from expensive fabrication processes that limit scalability for large area implementation, which would be desirable for applications such as textiles capable of scavenging energy from human motion or vibrations from large area structures, such as buildings, aircraft, or vehicles.

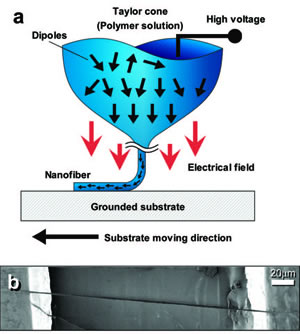

Recently, Chang et. al. reported on polymeric nanogenerators formed by a direct write method to synthesize poly (vinylidene fluoride) (PVDF) nanofibers. PVDF is a compliant material with good mechanical and piezoelectric properties, is chemically and environmentally stable, and is typically formed in thin film constructs for sensor and actuator applications. Deposited PVDF contains multiple crystalline phases and must be poled to obtain the necessary ß phase for efficient piezoelectric performance. Poling requires extremely high electric fields to be applied to the PVDF during processing, which is difficult for large area, high throughput manufacturing. In their approach, the authors employ near-field electrospinning (NFES) to synthesize PVDF nanofibers on compliant substrates providing in situ mechanical stretching and electrical poling by transforming the random dipole orientation within the nanofibers to predominantly ß phase. The nanofibers have diameters as small as 500 nm with lengths ranging from 100-600 µm, and are directly written across pre-patterned electrodes on a deformable substrate. Application of axial stress to the substrate by bending generates a piezoelectric potential.

Subsequent testing of the nanofiber power generators characterized performance as a function of applied strain, strain rate, and frequency, and demonstrated energy conversion efficiencies as high as 21.8%. With an average efficiency of 12.5% for all nanogenerators tested, the performance results were much greater than PVDF power generators made from experimental or commercial thin films. The authors further arranged and integrated multiple nanofibers to enhance the electrical output, thereby providing a means to control voltage, current, and matching impedance levels for specified applications. Incorporating the advantages of high conversion efficiency, scalable manufacturing, and facile integration strategies, PVDF nanofiber power generators provide the basis for self-powered textiles, embedded power sources for nanodevices and wireless sensors, and large area fabrics for portable electronics implementations.

Image reproduced with permission from Chang C, et.al. 2010. Direct-Write Piezoelectric Polymeric Nanogenerator with High Energy Conversion Efficiency. Nano Letters 10: 726 - 731. DOI: 10.1021/nl9040719. Copyright 2010 American Chemical Society.

This work is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported.