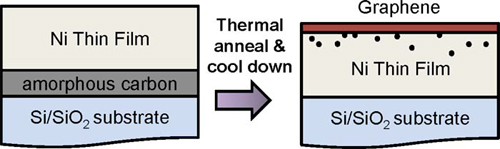

| Zheng and colleagues describe a method to synthesize large-area, transferrable graphene films by metal-catalyzed crystallization of amorphous carbon (a-C) through thermal annealing. |

Reviewed by Jeff Morse, PhD., National Nanomanufacturing Network

Due to its unique electrical, mechanical and optical properties, graphene has generated significant interest as a potential material component of electronics, energy, and sensor technologies. Yet, in applications such as electronics, an integration strategy is necessary that includes large area production of graphene sheets having controlled thickness and morphology. Methods of graphene production have emerged from the initial methods of generating small amounts for research studies --typically by mechanically exfoliating monolayers from bulk graphite--to alternative approaches conducive with large area processing. One approach, using chemical vapor deposition (CVD), takes advantage of existing process tools, yet suffers from difficulty in controlling the number of graphene layers over large areas due to the sensitivity of various process parameters. Recently, CVD of graphene on copper (Cu) surfaces has demonstrated control in achieving single-layer graphene sheets with the Cu behaving as a catalyst for graphene nucleation. In this method, crystallization of the graphene sheets is a self-limiting process. While this approach has exhibited high quality, uniform single layers scalable to large areas, it remains limited for synthesizing films having more layers.

Recently, Zheng et. al. reported on the synthesis of graphene films by metal-catalyzed crystallization of amorphous carbon (a-C) through thermal annealing. Beginning with a silicon dioxide coated silicon substrate (Si/SiO2), a layer of a-C in the 2.5-40 nm range is deposited by electron beam evaporation. This step is followed by the deposition of a nickel (Ni) or cobalt (Co) film of 100-300 nm. The thin films are then annealed in a tube furnace between 650-950 °C under an inert argon atmosphere at a pressure of ~1.7 Torr. After annealing, a graphitic layer is formed on the metal surface as the substrate is cooled at a rate of 20 °C/s.

Analysis of the film by Raman spectroscopy exhibited a multilayer graphene film having low defect density. The process is facilitated by the diffusion of carbon atoms from the a-C layer into the metal film during the thermal anneal step. During the cooling step, the carbon atoms precipitate on the free surface of the metal as the solid solubility limit is surpassed, with the metal behaving as a catalyst to the crystallization of graphene. The number of graphene layers was readily controlled by the thickness of the initial a-C and metal layers in combination with the anneal temperature and cool-down rate. In this manner, the process is effectively a limited-source method, as the source is the initial a-C layer. Both Ni and Co metal films resulted in quality graphene films. The authors further investigated Cu films as the metal catalyst with no graphene layers formed after annealing and cool down, likely due to the low diffusivity and solid solubility of C in Cu.

The authors also demonstrated that the graphene films could be transferred to other substrates. The metal-crystallized films were coated with a poly (methyl methacrylate) (PMMA) film followed by a liftoff step by removal of the metal layer with an acid etch. The detached graphene film was placed in a water bath after which it was transferred to a Si/SiO2 substrate. After dissolving the PMMA layer in acetone, followed by an isopropyl alcohol rinse, the transferred layer was characterized by Raman spectroscopy, showing similar quality of the film. The authors were also able to transfer the graphene film without the use of the sacrificial PMMA layer, thereby demonstrating the robustness of the process.

A facile approach for the controlled synthesis of graphene films scalable to large area substrates has been reported. The metal-catalyzed crystallization enables control of the number of graphene layers via a limited source approach. Further investigation will consider methods to from the graphene layers directly on the dielectric film, as well as lower the anneal temperature through the use of alternate metals.

Image reproduced with permission from Zheng M, et al. 2010. Metal-Catalyzed Crystallization of Amorphous Carbon to Graphene. Applied Phyiscs Letters 96 (063110). DOI: 10.1063/1.3318263. Copyright 2010, American Institute of Physics.

This work is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported.