Bulk metallic glasses (BMGs) are amorphous metallic alloys produced by melting and thermal quenching which exhibit desirable properties such as high strength and good formability (at reduced temperatures versus pure metals). As a result, these materials are ideal for patterning and controlling the morphology, with example applications in nanoimprint lithography molds, plastic-replacement components, and field emission devices. The ability to nanoengineer BMGs is particularly interesting for catalytic applications where high surface areas and precision compositional control are necessary. InterNano has previously highlighted work by (Schroers, Schroers and Taylor) in which the approach to nanostructured BMGs was demonstrated, and subsequently the formation of Pt-BMG nanostructures was studied. This approach provides a precision approach to tailor the morphology of bulk metallic compositions at the nanoscale. For applications in electrocatalytic surfaces, a method for tailoring the metal composition of the surface at the nanoparticle scale would enable additional optimization of material and surface properties.

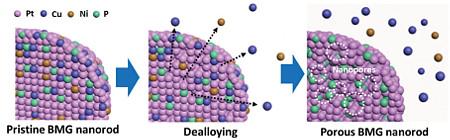

Recently, the Taylor group in the Chemical and Environmental Engineering Department at Yale University (Guided Evolution of Bulk Metallic Glass Nanostructures: A Platform for Designing 3D Electrocatalytic Surfaces) reported on their approach to modify the surface of Pt-based BMG alloys and nanostructures. In their work, the authors utilized subtractive approaches, for example dealloying the BMG surface, along with additive approaches, such as electrodeposition, enabling additional control and engineering of the BMG surface. Incorporating such post process steps allow the nanostructured BMG alloy to be further nanoengineered by using electrochemical cycling to leach less active metals from the surface composition, which increases the effective surface area by creating pores where the dealloying occurs. The authors employed a combinatorial approach to study ternary and quaternary compositions from it was determined that specific alloys have a parting limit for which the dealloying process stops. BMG nanorods were formed using an anodized aluminum oxide template, after which the nanorods were subjected to the dealloying process. Several electrochemical reactions were evaluated using the nanorods at various stages of surface modification to correlate the performance to level of dealloying, indicating control over surface area and exposure of noble metals as non-noble components are removed. Subsequently, additive processes, for example galvanic displacement deposition, were studied to incorporate specific materials such as Ru/RuO on the modified BMG surfaces in a controlled manner. Subsequent electrochemical analysis verified the increase in performance of the nanoengineered surfaces.

Precision control of metal surfaces, both in terms of composition and morphology, remains a significant challenge that could benefit a broad range of applications. The approach incorporating surface modification of Pt-based BMG alloys has shown to be an effective way to tailor the properties of nanostructured surfaces enabling a method to engineer the design of the material composition for specific applications as well as improve the utilization of precious metals for such applications. This approach further opens up numerous possibilities for metallic glass nanostructures and techniques demonstrated which can be extended for a wide variety of target applications ranging from other electrochemical reactions to sensors to surface coatings for enhanced durability or biocompatibility.

References:

Doubek, G., Sekol, R. C., Li, J., Ryu, W.-H., Gittleson, F. S., Nejati, S., Moy, E., Reid, C., Carmo, M., Linardi, M., Bordeenithikasem, P., Kinser, E., Liu, Y., Tong, X., Osuji, C. O., Schroers, J., Mukherjee, S. and Taylor, A. D. (2015), Guided Evolution of Bulk Metallic Glass Nanostructures: A Platform for Designing 3D Electrocatalytic Surfaces. Adv. Mater.. doi:10.1002/adma.201504504