Separation technology is at the heart of water purification, sewage treatment and reclaiming materials, as well as numerous basic industrial processes. Membranes are used to separate out the smallest, nanoscale particles and even molecules and metal ions. Prof. Boris Rybtchinski and his group of the Weizmann Institute of Science’s Organic Chemistry Department have developed a new type of membrane that could extend the life of a separation system, lower its cost and, in some cases, increase its efficiency as well.

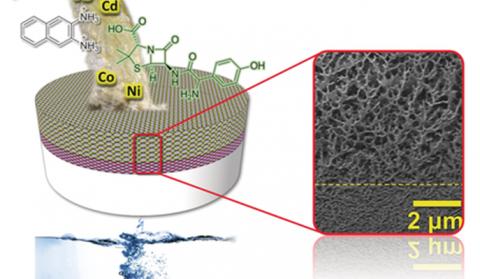

The membranes he and his group have created may be produced in different ways, with different materials, and they come together in water and contain water as a major component (the membranes are akin to hydrogels). The first-generation membranes the group developed were made of unique molecules that organize themselves into the membrane material. This property also enables the membrane to be easily recycled and the particles trapped in the separation process to be reclaimed. The membranes can separate particles based on size, from one to several nanometers.

The second-generation membranes also contain a second self-assembled polymer layer, thus broadening the range of applications for this technology. These new membranes can sustain high pressures and are capable of purifying water from poisonous heavy metals and organic molecules, showing for the first time that self-assembled “aqua materials” can be used for demanding industrial application. Unlike conventional materials, the self-assembled membranes can be easily disassembled; this is critical for fighting membrane fouling, which is the biggest challenge in membrane applications. The membrane fabrication process is simple, and their performance is excellent, making the technology inherently worthwhile, even before the ability to recycle and reuse them is taken into consideration. The latter, of course, is of enormous importance, as it renders the membranes sustainable. Indeed, the goal of creating sustainable nanomaterials is at the core of the research performed by Rybtchinski and his group.

Yeda Research and Development, which advances the industrial application of Weizmann Institute of Science research findings, is working on bringing this innovative technology to market.

Prof. Boris Rybtchinski's research is supported by the Solo Dwek and Maurizio Dwek Research School of Chemical Science, which he heads; the Leona M. and Harry B. Helmsley Charitable Trust; and Dana and Yossie Hollander, Israel.