As history often offers hints for the future, the experience in traditional manufacturing often helps us to identify the path to commercial scale production: integrated nanomanufacturing and nanoinformatics (INN).

In the past, high-volume production often required systematic knowledge regarding robust product/process design, synthesis or processing techniques, metrology and inspection, and process modeling and control. The successful transformation of quality and productivity in traditional manufacturing suggests the need of integrating engineering knowledge with advanced statistics in each stage of product life cycle.

However, unlike traditional manufacturing, nanomanufacturing involves product characteristics and process variables at multiple length scales. The process and product variations are therefore across multiple scales as well. The multiscale product/process variation (MPV) features the multiscale and multiphenomenon challenge in nanomanufacturing. Control of MPVs generally demands more information than variation control at a single scale. But there is a lack of measurement data, observation during processing, and physical knowledge at fine scales. The SEM (scanning electron microscope) or TEM (transmission electron microscopy) inspection is extremely time-consuming and costly. Data collection must be guided and optimized for MPV control in order to reduce the inspection cost. The current nanomanufacturing research mainly focuses on the processing techniques or synthesis methods of fabricating novel nano materials or devices. Nanomanufacturing and nanoinformatics barely connect with each other to model, control, and reduce the MPVs. The complexity of MPV control and the lack of information and knowledge demand INN research for quality and productivity improvement in nanomanufacturing.

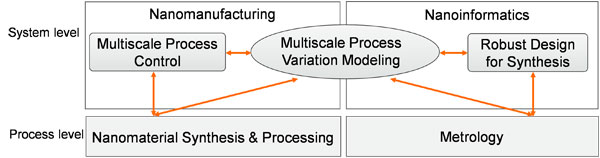

Under the premise that INN is essential for scalable nanomanufacturing, the subsequent issue is how NM and nanoinformatics are integrated for modeling and control of MPVs. An INN framework was proposed in Figure 1. As can be seen, the research in each critical stage is categorized into either nanomanufacturing or nanoinformatics. The key of integration is to establish MPV models that provide realistic description of synthesis processes under manufacturing uncertainties. The foundation of MPV modeling is the process-level understanding of nanomaterial synthesis and characterization (metrology). To address the system-level issues regarding quality and productivity, MPV modeling provides the basis for process monitoring and control, guided inspection and sensing strategy, and more efficient experimental design strategy for robust synthesis of nanomaterials. INN research is highly interdisciplinary and it is an exciting area for research and education for scale-up nanomanufacturing.

Reference

Huang, Q., 2011, “Integrated Nanomanufacturing and Nanoinformatics for Quality Improvement,” 44th CIRP International Conference on Manufacturing Systems, June 1-3, 2011, Madison Wisconsin (Invited)

Qiang Huang

Associate Professor and Gordon S. Marshall Early Career Chair in Engineering

Epstein Department of Industrial and Systems Engineering

University of Southern California

qiang.huang@usc.edu