Fabrication of three-dimensional (3D) objects through direct deposition of functional materials – also called additive manufacturing – has been a subject of intense study in the area of macroscale manufacturing for several decades. These 3D printing techniques are reaching a stage where desired products and structures can be made independent of the complexity of their shapes – even bioprinting tissue is now in the realm of the possible.

Applying 3D printing concepts to nanotechnology could bring similar advantages to nanofabrication – speed, less waste, economic viability – than it is expected to bring to manufacturing technologies.

In addition, pre-patterned micro- or nanostructures could be used as substrates, allowing researchers to realize unprecedented manufacturing flexibility, functionality and complexity at the nanoscale.

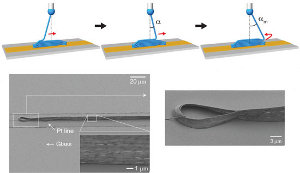

Researchers in Korea have now shown that nanoscale 3D objects such as free-standing nanowalls can by constructed by an additive manufacturing scheme. Even without the motion of the substrate, nanojets are spontaneously laid down and piled to yield nanowalls.

The team, led by Ho-Young Kim, a professor at Seoul National University, has published their findings in the January 28, 2014 online edition of Langmuir ("Toward Nanoscale Three-Dimensional Printing: Nanowalls Built of Electrospun Nanofibers").

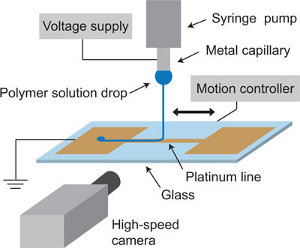

"Electrospinning that produces polymer nanojets is a relatively simple and inexpensive method to yield nanoscale fibers, but the fiber streams are so chaotic that control of individual fibers has been considered almost impossible," Kim explains to Nanowerk. "In our recent work, we have shown that an electrospun polymer solution jet, which tends to become unstable as traveling in the air due to Coulombic repulsion, can be stably focused onto a thin metal electrode line." Kim and his team also elucidated the fundamental electromechanical mechanism that enables the spontaneous stacking of a nanofiber onto itself to provide a physical basis behind this novel nanofabrication process.

In this novel method, a thin metal line on an insulating plate strongly focuses the electrical field, thus the whipping instability of the electrical nanojets is suppressed.

To stack the fibers in a controlled fashion, the researchers manipulate the fiber deposit into attracting the incoming nanojets rather than repelling them by draining the electrical charge quickly. Then they get a nanowall that lines the ground, implying that various free-standing structures can be created by patterning the microscale ground lines in a desired shape.

The construction of a free-standing nanowall is the most fundamental step to achieve 3D nanoprinting.

This process is so attractive because it needs only a power supply and a linear stage to build free-standing nanowalls after drawing metal microlines, all of which can be conducted under normal laboratory conditions.

Kim points out that this technique has a significant economic advantage as compared to conventional nanomanufacturing processes used to build nanowalls such as DRIE (deep reactive ion etching).

The current scheme of repeatedly stacking nanofibers onto a conducting line is suited for fabricating nanoelectrodes consisting of straight walls and nanochannel field effect transistors (FETs) utilizing insulating nanowalls as gaps of metal patterns.

Further sophisticated methods to control the nanojets have the potential to realize rapid 3D printing of complicated shapes, which can be used for bio scaffolds, nanofilters and even nanorobots.

However, further developments, such as lowering the nanojet speed and positioning the target place with high precision, are necessary to make the current focused electrojetting process fully capable of 3D printing of complicated shapes.

"Full 3D control of an electrospun nanojet would possibly revolutionize the current nanofabrication technology, which we aim to achieve in the long run," says Kim. "However, we believe that such great achievement cannot be made with a single step. Further development for the precise control of the nanojet could realize full 3D nanofabrication."

Source: Nanowerk

Images reprinted with permission from Toward Nanoscale Three-Dimensional Printing: Nanowalls Built of Electrospun Nanofibers Minhee Lee and Ho-Young Kim, Langmuir Article ASAP. Copyright 2004 American Chemical Society.