Many researchers are investigating the development of flexible solar cells in hopes of improving efficiency and lowering manufacturing costs. As an important member of the organic photovoltaics (OPV) family, polymer solar cells draw the most research interest, due to the relatively high power conversion efficiency achieved. However, compared to the high efficiencies (>10%) of inorganic solar cells, the best polymer solar cells (6-7%) still show a lower efficiency.

Improved nanomorphology is seen as key to improving the efficiency of organic solar cells. One particular nanotechnology approach would use nanoimprint lithography (NIL) to produce precisely nanostructured devices rather than using chemical methods of manufacturing.

Nanoimprinting is an emerging technology that’s been used to produce various electronic and optical devices by imprinting the pattern from a mold onto a surface (see for instance the European NAPANIL project that targeted scalable nanomanufacturing processes for arbitrary 3-dimensional surfaces with features well below 100 nm in the fields of optical components and life sciences).

A review paper in ACS NANO ("Nanoimprinted Polymer Solar Cell") sets out to develop a comprehensive understanding of nanoimprinted OPVs. The authors, led by Walter Hu, an Associate Professor of Electrical Engineering, and Anvar Zakhidov, a professor of physics, both at UT Dallas, review and compare different nanoimprint lithographic techniques employed to fabricate nanoimprinted OPVs in literature.

Based on this review, they then discuss the geometric effects of imprinted nanostructures on device performance. They also review the effects of nanoimprint on polymer chain alignment and its influence on charge transport. They introduce the progress on electrode patterning for polymer solar cells. Finally, the current challenges and future tasks for nanoimprinted OPVs are previewed.

According to the authors, the goal of this review is to help develop a better understanding of nanoimprinted OPVs so as to unleash the full potential of this emerging technique toward significant improvements of OPV performance.

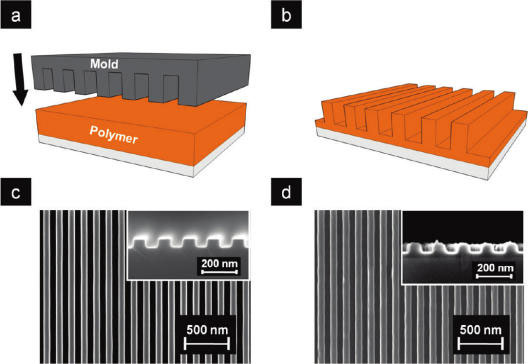

The figure below shows the general process flow for NIL:

For the nanoimprinted solar cells to obtain high performance, the complete infiltration of acceptor materials into the nanostructured donor polymer layer is critical in order to form an intimate and large interfacial area junction for efficient exciton dissociation, charge separation, and collection.

So far, three fabrication methods have been used to fabricate nanoimprinted OPVs:

Spin-coating has been proven as an effective, simple, and low-cost process to fill acceptor materials into imprinted donor materials. However, for some acceptors which have very low solubility in common solvents, or for which orthogonal solvents cannot be found, spin-coating is not feasible.

To overcome the drawbacks of spin-coating, physical vapor deposition (PVD) can be used as an alternative method to deposit acceptor materials in nanoimprinted solar cells. However, limitations exist for the fabrication of imprinted OPVs using this method. For example, typically a high vacuum is required for PVD, making this method more costly and slower. In addition, PVD is difficult to realize for materials which do not have the required vapor pressure for evaporation, such as conjugated polymer acceptors.

A third method to fabricate nanoimprinted OPVs is lamination. Here, a double nanoimprinting process allows the formation of nanostructured polymer heterojunctions of composition and morphology that can be selected independently.

In literature, most nanoimprinted OPVs have architectures where fullerene acceptors were infiltrated into nanoimprinted polymer nanostructures. However, some studies have shown that NIL could also be used to pattern the blended active layer in polymer solar cells directly to improve the device performance.

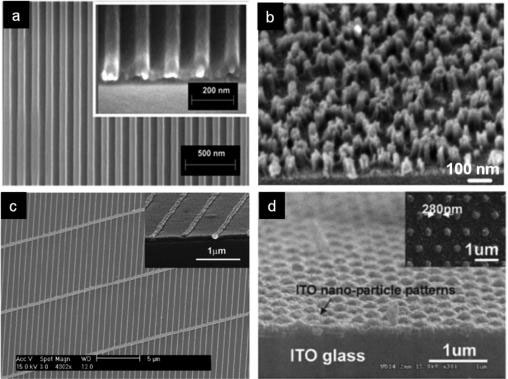

In addition to active layer patterning to improve exciton dissociation and charge transport, NIL can also be used to pattern electrodes for OPVs in order to improve light transmission and charge collection. As the authors point out, not only can the polymer electrode be patterned by NIL to improve solar cell performance, but many inorganic electrode materials can also be improved by this technique.

Concluding their review, the authors note that much progress has been achieved in nanoimprinted polymer solar cells. "However, there are still many challenges existing in this field. To further widen the application of NIL in OPVs, three important factors, including the process window, cost and throughput, and efficiency, need to be considered."

1) Process Window for New Materials

The first challenge comes from the unknown process window, that is, the question of whether NIL can be applied to new conjugated materials which give higher efficiency than P3HT. To date, most work on nanoimprinted OPVs has been focused on P3HT, due to its convenience for nanoimprint patterning. However, many groups have reported much higher efficiencies by using new conjugated polymers. If NIL is to become a useful technique for the organic solar cell industry in the future, the feasibility of using NIL to improve the device performance of these new polymers needs to be addressed.

2) Cost and Throughput

It is critical for nanoimprinted OPVs to simplify fabrication, lower costs, and increase throughput. Although many people have demonstrated that the power conversion efficiency of polymer solar cells can be improved by NIL, the required fabrication procedures are more complicated and thus more costly than the most common blended bulk heterojunction solar cells.

3) Efficiency

The third challenge, obviously, is how to further improve the performance of nanoimprinted polymer solar cells. In literature, people have shown that devices made by this technique give higher efficiencies than bilayer structures, but the highest efficiencies using the same donor and acceptor materials are still lower than the best reported performance using the bulk heterojunction structure.

Source: Nanowerk