| Cheng, et.al., demonstrate a new superlattice patterning methodology that shows promise for specific patterns and shapes in two and three dimensional configurations. |

A review by Jeff Morse, PhD., National Nanomanufacturing Network

While creating superlattices by evaporation of nanoparticles in solution has exhibited semblances of patterned crystal formation, the self-assembly of crystal patterns remains difficult to reproduce. This results from limited control over uniformity of evaporation fields that can lead to capillary flow within the droplet solution, along with fluid fluctuations during late stage drying effects that lead to irregular features and limited ordering. Such drying-mediated self-assembly processes face challenges for the controlled patterning of superlattice structures while maintaining internal ordering. Furthermore, when combining the dynamics of wetting and dewetting of specified surfaces structures, the problem becomes even more complex from a control standpoint. Researchers have previously shown that incorporation of chemically or physically patterned surfaces enable control over the nucleation and growth of superlattice structures from patterned microdroplets containing nanoparticles. While this approach demonstrated reproducibility of internal ordering of the nanoparticles, specific sizes and shapes of the crystal structures were difficult to achieve.

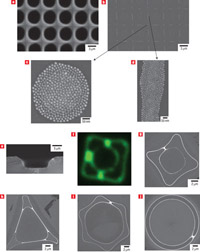

Recent results published by Cheng, et.al., demonstrated a new superlattice patterning methodology that shows promise for specific patterns, shapes, and configurations in two and three dimensional configurations. Their approach incorporates micropatterned moulds to control microdroplet size and dewetting dynamics to precisely define shapes, position, and contact line boundaries of the superlattice structures. First creating a micropatterned mould from polydimethylsiloxane (PDMS), a nanoparticle solution is sandwiched between the mould and a solid substrate. PDMS is a fairly soft material that readily deforms when pressure is applied to the top surface. Controlling the dewetting dynamics of the nanoparticle microdroplets through appropriate pressure and mould geometry produces structures that maintaining a high degree of internal ordering. The results demonstrate a range of structures and patterns, including alignment of conductive nanoparticle structures to existing microelectrode arrays on the substrate.

Combining a top-down patterning approach with the bottom-up method of nanoparticle self-assembly provides an innovative and versatile methodology to produce highly ordered nanostructures having specific patterns, locations, and properties. Further variations of wetting properties of the mould and substrate surfaces, along with the solution in which the nanoparticles are suspended may additionally improve the capabilities for this technique. Additionally, the soft PDMS mould material has a tendency to deform when pressure is applied such that the precision of the patterned structures is impacted. Other more rigid mould materials must be studied in order to address this particular issue, and promise to further improve the overall pattern precision.

Image reprinted by permission from Macmillan Publishers Ltd: Nature Nanotechnology (Chen, W., et. al., Nanopatterning self assembled nanoparticle superlattices by moulding microdroplets. Nature Nanotechnology 3 (2008) 682 – 690.), copyright (2008).

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported.